- Description

- Specifications

- Documents

Programmable DC Electronic Load

- 120 A, 80 V, or 600 W max.

- Compatibility between 6310 and 6310A

- Synchronization with multiple loads

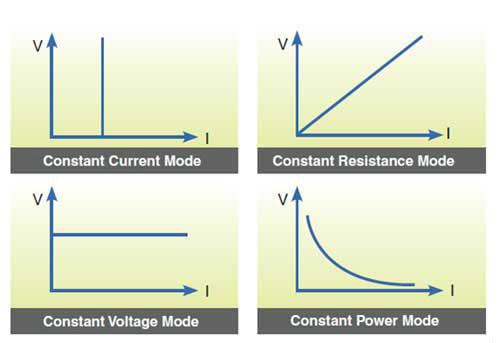

- Flexible CC, CR, CP and CV operation modes

- Dynamic loading with speeds up to 20kHz

- Fast response of 0.32mA/s - 10A/s slew rate

- Minimum input resistance allows the load to sink high current at low voltages

- Real time power supply load transient response simulation and output measurements

- Takes 2 slots

- User programmable 100 sequences. Front panel input status for user-friendly operation

- High/Low limits of testing parameters to test GO/NG

- Digital I/O control

- Over current protection (OCP) testing function

- 16-bit precision voltage and current measurement with dual-range

- Remote sensing capability

- Short circuit test

- Self-test at power-on

- Full Protection: OV, OC, OP, OT and reverse protection

- USB, GPIB & RS-232 interface (mainframe dependent)

The 63106A load module is compatible with the 6310 series mainframes (6312/6314). In addition, the remote control commands will be compatible between the 6310 and the 6310A series without needing to re-writing any remote control programs. It can be operated in constant current, constant voltage, constant power and constant resistance and may be placed in parallel for increased current and power.

This programmable DC electronic load module is designed with state-of-the-art technology and connects all the power MOSFET devices in parallel to insure high accuracy load control with a minimum drift of less than 0.1%+0.1%F.S. of the current setting. Chroma's use of FET technology provides minimum input resistance and enables the load to sink high current even at very low voltages.

The 63106A can simulate a wide range of dynamic loading applications. The waveforms programmable parameters include: slew rate, load level, duration and conducting voltage. In addition, up to 100 sets of system operating status can be stored in EEPROM and recalled instantly for automated testing applications.

Real time measurement of voltage and current are integrated into each 63106A load module using a 16-bit precision measurement circuit. The user can perform on line voltage measurements and adjustments or simulate short circuit test using the user friendly keypad on the front panel.

Versatile System Configuration

Chroma 63102A Programmable Electronic Load integrates microprocessor capabilities into each load module and mainframe to provide simple and accurate parallel operation to optimize the speed and control among multiple load modules. All load modules may be configured to work synchronously, to test multiple outputs simultaneously, thus simulating real life applications.

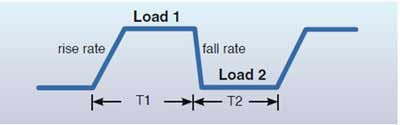

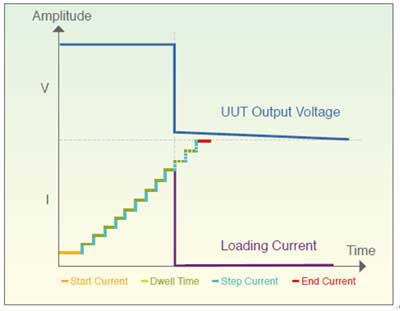

| Dynamic Loading and Control Modern electronic devices operate at very high speeds and require fast dynamic operation of their power providing components. To satisfy these testing applications, the 63102A load offers high speed, programmable dynamic load simulation and control capability. The figure below shows the programmable parameters of the 6310A modules: |

|

Parallel Control

The 63102A provides parallel control, which enables high power testing when a single module cannot meet the requirement of high power applications. Two or more load modules can be paralleled together to achieve the desired loading.

In addition, the 63106A, through its synchronized controls, provides an efficient solution for testing single output AC to DC or DC to DC converters by controlling multiple loads.

Powerful Measurements

Each 63106A load module has an integrated 16-bit precision A/D converter for voltage measurement with an accuracy of 0.025%+0.025% of full scale. The built-in resistive load current sensing circuit is capable of measuring current with an accuracy of 0.05%+0.05% of full scale. Also, short circuit can be simulated. All measurements are done using remote sensing to eliminate any error due to voltage drops along the measurement path. The user can also select from a complete set of voltage and current measurements.

OCP Test

Modern switching power supplies are designed with over current protection (OCP) circuitry; therefore, it is important to test the OCP circuitry to make sure it is functioning within its designed specifications.

By simply choosing the channel and setting the OCP parameters (start current, end current, step current and dwell time) from the front panel, the 63106A provides a fast and easy OCP testing solution, and will automatically detect the OCP point, making it an ideal solution for design verification as well as production line testing.

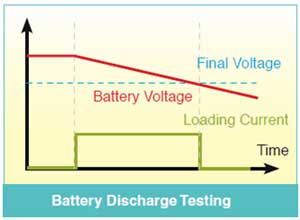

Timing Function For example, the figure on the right shows the internal timer starting at load ON, and ending when the battery voltage reaches the final voltage. The Timing function can be used in testing battery and super capacitor discharge, or other similar applications. |

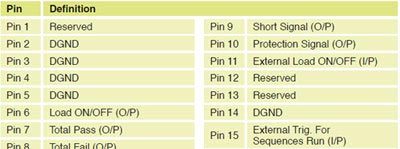

Digital I/O |