- Description

- Specifications

- Documents

- Mainframes holds four or two modules, up to 8 loads total

- Parallel load modules up to 1,200 W total power, 240 A total current

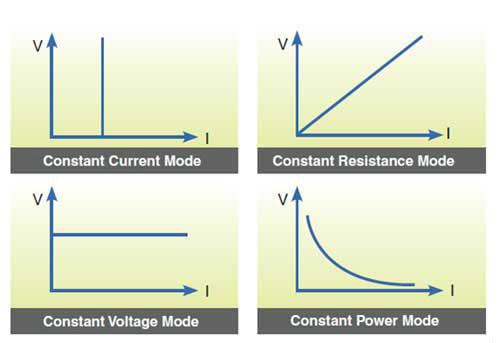

- Constant Current, Constant Resistance, Constant Voltage, Constant Power modes

- Dynamic loading to 20 kHz with internal pulse generator

- Fast, adjustable slew rate from 0.32 mA/µS to 10 A/µS

- Built-in voltage, current, & power measurement

- Minimum input resistance allows the load to sink high current at low voltages

- Real time power supply load transient response simulation and output measurements

- User programmable 100 sequences. Front panel input status for user-friendly operation

- High/Low limits of testing parameters to test GO/NG

- Remote sensing capability

- RS-232 Interface included

- Optional GPIB and USB Interface

Versatile System Configuration

Chroma 6310A Programmable Electronic Load integrates microprocessor capabilities into each load module and mainframe to provide simple and accurate parallel operation to optimize the speed and control among multiple load modules. All load modules may be configured to work synchronously, to test multiple outputs simultaneously, thus simulating real life applications.Compatibility With 6310 Series

The 6310A series load modules will be compatible with the 6312A mainframe (for 2 load modules) and the 6314A mainframe (for 4 load modules). In addition, the remote control commands will be compatible between the 6310 and the 6310A series without needing to re-writing any remote control programs.

Module Load Design

The

Chroma 6314A 1200W and 6312A 600W electronic load mainframes accept the user-installable

6310A series load modules for easy system configuration and will mount in a

19" instrument rack. The 6314A holds up to four 63102A load modules, which

will result in an 8-channel 100W/channel load with standard front-panel inputs.

This makes it ideal for testing multiple output switching power supplies and

multiple DC-DC converters. There are also higher wattage modules that may be

mixed and matched for an even more versatile system. Additionally, the GO/NG

output port is useful for UUT's pass/fail testing on an automated production

line. All modules on the 6314A/6312A mainframe share a common GPIB address

to synchronize and speed up the control of the load modules and the readback

of data.

The

Chroma 6314A 1200W and 6312A 600W electronic load mainframes accept the user-installable

6310A series load modules for easy system configuration and will mount in a

19" instrument rack. The 6314A holds up to four 63102A load modules, which

will result in an 8-channel 100W/channel load with standard front-panel inputs.

This makes it ideal for testing multiple output switching power supplies and

multiple DC-DC converters. There are also higher wattage modules that may be

mixed and matched for an even more versatile system. Additionally, the GO/NG

output port is useful for UUT's pass/fail testing on an automated production

line. All modules on the 6314A/6312A mainframe share a common GPIB address

to synchronize and speed up the control of the load modules and the readback

of data.

Application of Specific Load Simulation

The 6310A load modules operate in constant current, constant voltage, constant power or constant resistance to satisfy a wide range of test requirements. For example, the test of a battery charger can be simulated easily by setting the load to operate in constant voltage.

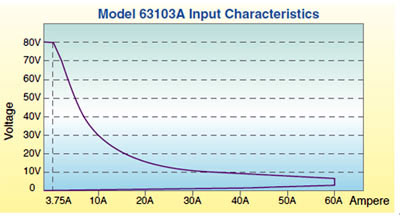

Each load module is designed with state-of-the-art technology and connects all the power MOSFET devices in parallel to insure high accuracy load control with a minimum drift of less than 0.1%+0.1%F.S. of the current setting. Chroma's use of FET technology provides minimum input resistance and enables the load to sink high current even at very low voltages. For example, the model 63103A is capable of sinking 60A at 1V, and well-suited for testing the new 3.3V low voltage power supplies. Low voltage operation, down to zero volts, is possible at reduced current levels.

The 6310A load module uses a photo coupler for isolation between the output and control sections, thus each load is isolated and floating. The user can use multiple load modules independently to test multi-output power supplies, or parallel them for high power testing applications. |

|

|

Dynamic Loading and Control

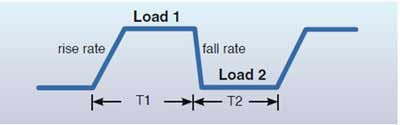

Modern electronic devices operate at very high speeds and require fast dynamic operation of their power providing components. To satisfy these testing applications, the 6310A loads offer high speed, programmable dynamic load simulation and control capability. The figure below shows the programmable parameters of the 6310A modules:

The programmable slew rate makes the simulation of transient load change demanded by real life applications possible. The 6310A internal waveform generator is capable of producing a maximum slew rate at 10 A/μs, and dynamic cycling up to 20 kHz. It's dedicated remote load sense and control circuit guarantee minimum waveform distortion during continuous load changes.

Parallel Control

The 6310A provides parallel control, which enables high power testing when a single module cannot meet the requirement of high power applications. Two or more load modules can be paralleled together to achieve the desired loading. The 6310A comes with RS-232 as standard for remote control and automated testing applications. The USB and GPIB interfaces are available as options.

In addition, the 6310A, through its synchronized controls, provides an efficient solution for testing single output AC to DC or DC to DC converters by controlling multiple loads. The 6310A provides the capability to test up to 8 UUTs at a time.

Powerful Measurements

Each 6310A load module has an integrated 16-bit precision A/D converter for voltage measurement with an accuracy of 0.025%+0.025% of full scale. The built-in resistive load current sensing circuit is capable of measuring current with an accuracy of 0.05%+0.05% of full scale. Also, short circuit can be simulated. All measurements are done using remote sensing to eliminate any error due to voltage drops along the measurement path. The user can also select from a complete set of voltage and current measurements.

OCP Test

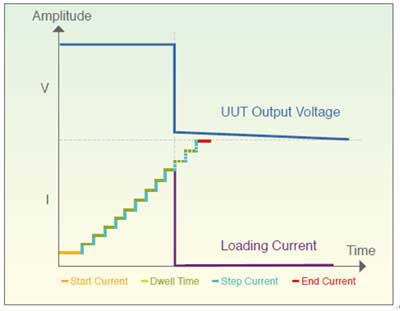

Modern switching power supplies are designed with over current protection (OCP) circuitry; therefore, it is important to test the OCP circuitry to make sure it is functioning within its designed specifications. The 6310A series provides an easy and fast solution for this testing.

By simply choosing the channel and setting the OCP parameters (start current, end current, step current and dwell time) from the front panel, the 6310A series provides a fast and easy OCP testing solution. The 6310A series will automatically detect the OCP point, making it an ideal solution for design verification as well as production line testing.

Timing Function

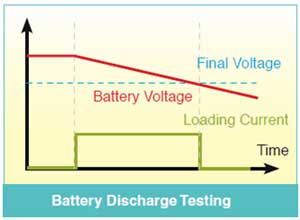

For example, the figure on the right shows the 6310A internal timer starting at load ON, and ending when the battery voltage reaches the final voltage. The Timing function can be used in testing battery and super capacitor discharge, or other similar applications. |

Digital I/O

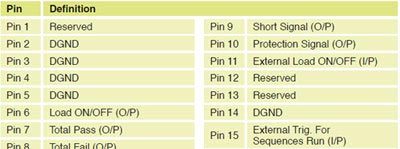

|

| 6310A Series Load Modules | ||

|---|---|---|

|

63101A

40 A, 80 V, 200 W |

63106A

120 A, 80 V, 600 W (2 slots) |

63112A

240 A, 80 V, 1200 W (4 slots) |

|

63102A Dual Channel 20 A, 80 V, 100 W (x2) |

63107A

Dual Channel 40 A & 5 A, 80 V, 250 W & 35 W |

63113A

20 A, 300 V, 300 W |

|

63103A

60 A, 80 V, 300 W |

63108A

20 A, 500 V, 600 W (2 slots) |

63115A

10 A, 600 V, 300 W |

|

63105A

20 A, 500 V, 300 W |

63110A LED Simulating 2 A, 300 V, 100 W (x2) |

63123A-120

70 A, 120 V, 350 W |