- Description

- Technical Manuals

- Specifications

- Documents

Additional shipping charges will be applied after checkout

TestEquity's Model 155 Benchtop Temperature Chamber combines best-in-class energy efficiency with outstanding temperature control.

Using patented control architecture, it consumes 74% less energy than previous models to maintain 0°C. The chamber features a control tolerance of less than ±0.08°C, operates over a range of -20°C to +130°C with 0.01°C display resolution, and provides 0.55 cubic feet of workspace. With the ability to control the DUT temperature directly, air temperature is precisely over-driven to achieve fast temperature settling times during transitions.

- 0.55 Cu Ft Workspace, 12W x 8H x 10D (15.73 liters)

- -20°C to +130°C Temperature Range with 0.01°C resolution

- F4T Touch Screen Controller with Integrated Limit Controller

- Air Temperature or Part Temperature Control

- Platinum RTD Temperature Sensors for the Highest Possible Accuracy

- 3" x 1.75" Cable Slots on Left and Right Side

- Compact Size for Benchtop Use

- Reversible Door

- Non-CFC Single-Stage Refrigeration - No LN2 or CO2 Required

- High Efficiency Tri-Mode Cooling for up to 74% Power Savings (Patent Number 10,126,032)

- 115/230V Switchable Input - Plugs Into Any Outlet

- 3 Year Parts, 1 Year Labor Warranty

- Made in the USA

TestEquity's new Model 155 Benchtop Temperature Chamber combines best-in-class energy efficiency with outstanding temperature control. Using patent-pending control architecture, it consumes 74% less energy than previous models to maintain 0°C. The chamber features a control tolerance better than ±0.08°C, operates over a range of -20°C to +130°C with 0.01°C display resolution, and provides 0.55 cubic feet of workspace. With the ability to control the DUT temperature directly, air temperature is precisely over-driven to achieve fast temperature settling times during transitions.

Tri-Mode Cooling ControlIn every other chamber on the market, the compressor always runs at full speed when cooling, regardless of how light the demand for cooling is. This wastes a considerable amount of energy and dissipates extra heat into the room. TestEquity's Model 155 uses a miniature DC Variable Speed Compressor and patented control architecture (Patent Number 10,126,032) to achieve unprecedented energy savings and robust temperature control.

Mode 1 - Cools as fast as possible. Compressor runs at 100% speed, refrigerant flow is at 100%.

Mode 2 - Compressor speed begins to vary when approaching the temperature set point or maintaining set points when the demand for cooling is high. The refrigerant flow is simultaneously pulse width modulated as required.

Mode 3 - When demand for cooling is minimal, such as holding a temperature set point after stabilization, the compressor runs at minimum speed. The refrigerant flow is pulse width modulated to maintain the temperature set point. This mode saves 40% on energy consumption compared to the same compressor running at full speed. When compared to our popular Model 107, the total energy savings is 74%.

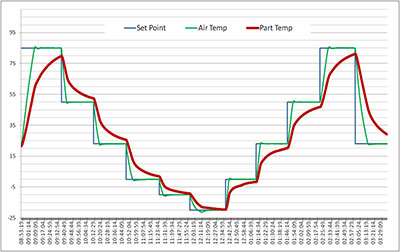

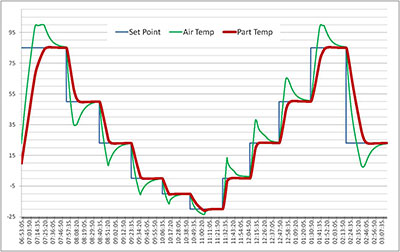

Part Temperature ControlIn all temperature chambers, the temperature of your DUT will always lag the air temperature due to its mass and the proximity from the air source. This causes the DUT to take a significant amount of time for its temperature to stabilize after the ar temperature has reached its set point. Additionally, the DUT may never reach the desired set point temperature, especially if it is energized. Part Temperature Control eliminates these issues. Part Temperature Control (also known as cascade control) is a multi-loop control system where the air temperature set point (Inner Loop) is determined by deviation of the part temperature (Outer Loop) from its set point. The controller is configured at the factory to allow the Air Temperature to deviate up to +10°C or –10°C from the Part Temperature set point. This allows the air temperature to be precisely "overdriven" to achieve the fastest temperature settling times during transitions.

| Air Temperature Control | Part Temperature Control | |

|

|

|

| DUT never quite reaches the temperature setting. Longer test time if you actually wait for the DUT to reach Set Point. |

Air temperature is biased higher/lower in a precise manner for the fastest response at the DUT. |

The F4T is our next-generation controller. Featuring a touch-screen interface, it's exceptionally easy and intuitive to use. Includes RS-232 and Ethernet interfaces. GPIB is available as an option.

| F4T Feature | F4T Benefit |

| 4.3 inch TFT Projected Capacitive (PCAP) color graphic touch screen | Modern interface for quick entry and readout of parameters and functions |

| Direct alphanumeric parameter entry | Quick and unambiguous entry of parameters for ease-of-use |

| Multiple levels of password security | Prevent tampering of critical parameters and processes by unauthorized persons |

| Profile archiving and transfer via USB Flash Drive | Quickly and easily transfer profiles to multiple chambers |

| Data Logging with transfer via USB Flash Drive or LAN | Simplify your documentation process |

| Graphical Trend Display | Eliminate circular chart recorders which have limited usefulnes |

| SCPI Commands | Easy programming of set points and readback of chamber conditions via Ethernet |

| F4 Compatibility Mode for most frequently used commands | Use your existing software that was written for the original F4 |

| NEMA 4 / IP65 Rated | Front panel protects the controller against damage from dust and water intrusion |

More about the F4T Touch Screen Controller >>

Plugs in to any outlet worldwide.Since the Model 155 uses a DC compressor, we are able to power the cooling and heating systems using an internal DC power supply. This allows the Model 155 to operate from 90 to 132VAC or 180 to 264VAC, 50 Hz or 60 Hz, with a rear panel switch for voltage range selection.

Cable slot on the left and right side.A cable slot provides easy entry and removal of wires and sensors that are attached between your test sample and equipment outside the chamber without having to remove the wires. A silicone plug is provided to seal the cable slot.

Compare the Model 155 to our popular Model 107 and see the many advantages.| Model 155 | Model 107 | |

| Interior | 12W x 8H x 10D (0.55 cu ft) |

12W x 9H x 11.25D (0.7 cu ft) |

| Exterior | 16.38 W x 21.88 H x 22.72 D, 88 lbs | 16.5W x 26H x 25.25D, 125 lbs |

| Input | 90 to 132V, 6A, 50/60 Hz or 180 to 264V, 3A, 50/60 Hz Switchable voltage range in a single model |

107: 120V, 10A, 60Hz 107-EX: 230V, 5A, 50 Hz These are two different models |

| Power Consumption at 0°C | 230 VA | 875 VA |

| Temperature Range | -20°C to +130°C | -42°C to +130°C |

| Temperature Controller | F4T Touch Screen Controller with Integrated Hi/Lo Limit Controller |

F4 or F4T Controller EZ-Zone Hi/Lo Limit Controller |

| Display Resolution | 0.01°C | 0.1°C |

| Control Tolerance | ±0.05°C Typical | ±0.2°C Typical |

| Temperature Sensor | Platinum RTD | Thermocouple |

| Part Temperature Control | Standard | Optional (+$ for F4T-T-CASCADE) |

| Access Ports | 3in x 1.75in Cable slot on left and right side (circular ports are not available) |

3in Circular port on left and right side (cable notches are not available) |

| Reversible Door | Yes | Yes |

| Hinges | Lift-Off | Bolt-On |