Condition:New

- Description

- Specifications

- Documents

Features and Specifications

Oil Operated - Single PCU - Hydraulic Deadweight Tester

Unit: kgf/cm2

Pressure Range: 20 to 1,400 kgf/cm2

Pressure Range Increment: 2 kgf/cm2

Accuracy: +/- 0.015% of reading (+/- 0.008% optional)

Materials of Construction:

Piston material: Tungsten carbide with nickel binder Density: 15.0 g/cm3Cylinder material: Hardened martensitic steel Tungsten carbide

Coefficient of expansion: Oil piston/cylinder 16.5 ppm/Celsius

Reservoir Volume: 150 cm3 (9.2 in3)

Operating Fluid: Mineral oil Shell spindle oil 22, our reference 55-655, viscosity 40 cs at 20 C (68 F)

Highlights

Built-in Priming Pump allows for purging and initial generation of pressure

High quality screw press for pressure generation and fine control

Clear reservoir allows for easy visual inspection of fluid cleanliness

Mounted spirit level with adjustable feet

Units can be trimmed to local gravity FOC

P3116-KGCM2 Overview

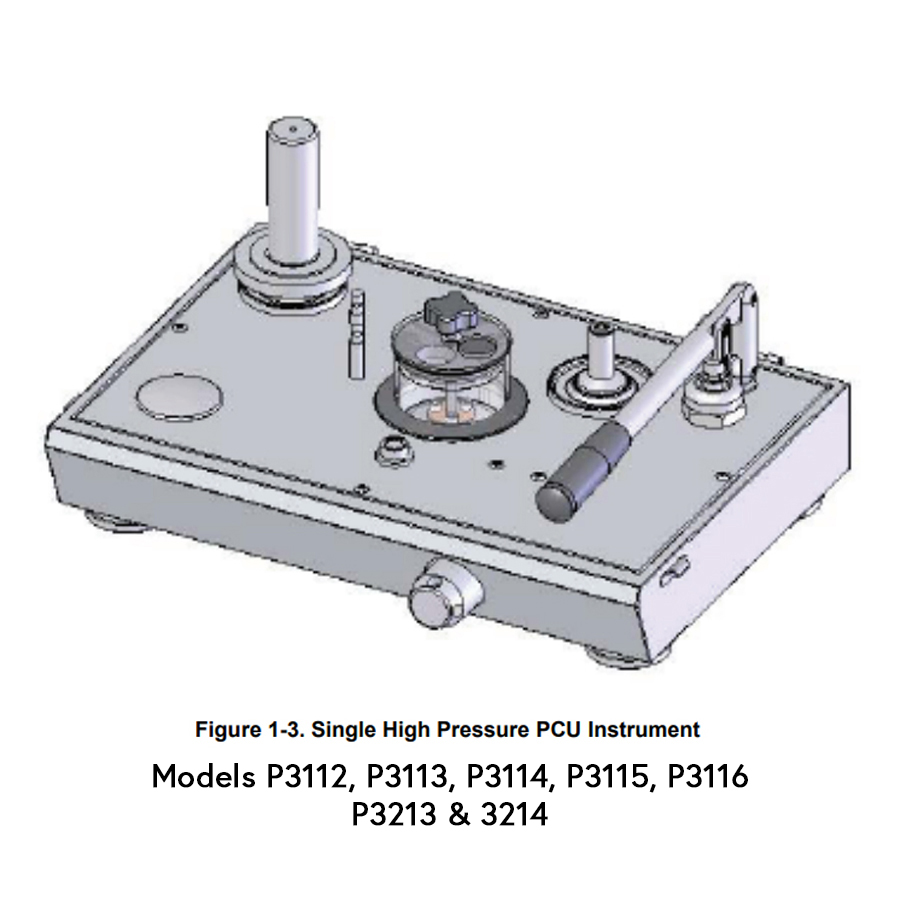

The P3116-KGCM2 Deadweight Tester (DWT) is a single high-pressure PCU instrument used for accurate pressure calibrations. It’s a high-performance pressure standard for pressure measurement, utilizing the well-proven piston-gauge system. The instrument’s piston/cylinder assembly is manufactured to the highest standards, with certified accuracies traceable to International Standards Laboratories such as the National Institute of Standards and Technology (NIST). The tester is part of the P3100 series, whose features are designed to improve accuracy and performance, increase reliability, and simplify operation.

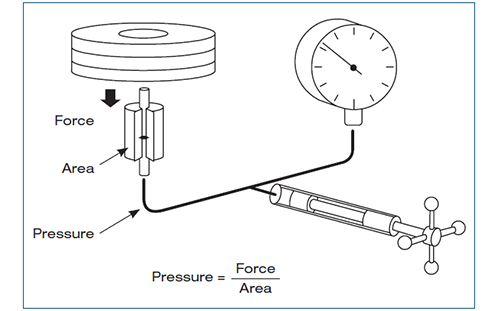

Operating Principle of a DWT

Deadweight testers serve as the fundamental benchmark for gauging pressure. They employ a tried-and-true piston-gauge system, which includes a vertically oriented piston and cylinder assembly that has been precision lapped. Precisely calibrated weight masses, representing force, are placed on the piston, representing area, which rises unimpeded within its cylinder. These weights counterbalance the upward force generated by the system’s pressure.

The pressure is determined when it is applied to a properly rotating and levitating piston. The total pressure calculated is the summation of the weights in addition to the weight assembly of the piston carrier.

P3100 Series of Deadweight Testers

The P3100 Series is the culmination of over 50 years of experience in the production and design of high performance pressure standards. With features designed to improve accuracy and performance, increase reliability and simplify operation these deadweight testers can be used to calibrate virtually any pressure sensing device, including transducers, transmitters, gauges or pressure switches.

The P3100 Models are available in single or dual piston formats for increased operating ranges. Units can be supplied in psi, bar, kgf/cm², and MPa. These robust instruments are highly accurate, quick and easy to use. Units feature a built-in priming pump for large volume applications, piston flotation indicators and a high quality screw press for fine pressure control.

Instrument Base

The hydraulic system comes in three fundamental types: models with low pressure, high pressure, and dual pistons. The creation and regulation of pressure are handled by a high-quality screw press situated at the tester’s front. All hydraulic models come standard with an integrated hand pump to prepare the system and handle substantial volume needs.

Categories of P3000 Models

There are many models in the P3000 product (including the P3100 and P3200), so for the purpose of this uncertainty analysis they are categorized as shown below.

*Full model names include variations depending on the nominal unit of measurement and inclusion of a built-in pressure pump.

Category | Range | Model* | |

|---|---|---|---|

Vacuum | -3 to -100 kPa (-30 to -1000 mbar, -1 to -30 InHg) | P3011, P3022 (VAC), P3023 (VAC), P3024 (VAC) | |

Low Pressure Gas | Positive gauge ranges up to 200 kPa (up to 30 psi) | P3012, P3013, P3023 (HP) | |

Medium Pressure Gas | 1000 and 3500 kPa (150 and 500 psi) | P3014, P3015, P3024 (HP) | |

High Pressure Gas | 7000 and 14000 kPa (1000 and 2000 psi) | P3031, P3032 | |

Low Pressure Oil | 3.5 and 14 MPa (500 and 2000 psi) | P3111, P3112, P3123(LP), P3124(LP), P3125(LP) | |

Medium Pressure Oil | 35 and 70 MPa (5000 and 10000 psi) | P3113, P3114, P3123(HP), P3124(HP) | |

High Pressure Oil | 110 MPa and 140 (16000 and 20000 psi) | P3115, P3116, P3125(HP) | |

Very High Pressure Oil | l 200, 260 and 400 MPa (30000, 40000 and 60000 psi) | P3830, P3840, P3860 | |

Low Pressure Water | 3.5 MPa (500 psi) | P3211, P3223(LP), P3224(LP) | |

Medium Pressure Water | 35 and 70 MPa (5000 and 10000 psi) | P3213, P3214, P3223(HP), P3224(HP) | |

Piston/Cylinder Assemblies

The piston/cylinder assembly is the heart of each deadweight tester. They are manufactured from materials that provide stability, durability, and low thermal coefficients and distortion. Fluke's experience and knowledge of piston/cylinder production and calibration ensures the precision and performance required for today’s demanding calibration requirements.

Masses

Standard weight masses are series 3 nonmagnetic austenitic stainless steel. Each mass is marked with the serial number of the instrument and the nominal pressure value relative to the high or low-pressure piston, when applicable. Optional fractional weights are stainless steel and/or solution heat treated aluminum.

Minimum Standard Weight Increments

Up to 500 psi (35 bar): 1 psi (0.1 bar)

500 psi to 5 000 psi (35 bar to 350 bar): 10 psi (1 bar)

5 000 psi to 20 000 psi (350 bar to 1 400 bar): 20 psi (2 bar)

Model P3112: 1 psi (0.1 bar)

Gravity

Gravity varies significantly with geographical location and this variation has a direct effect on the force of the weights and the accuracy of the deadweight tester. Each instrument can be trimmed to local gravity at no extra cost. If unspecified, instruments will be calibrated to Standard Gravity at 980.665 cm/s2.

PressCal Software

PressCal software is an optional Windows-based software program that allows users to easily apply all necessary corrections (e.g. local gravity, temperature, pressure head, etc.) to enhance the deadweight tester performance. Calibration details are then stored and/or used to automatically create a calibration certificate. The use of PressCal allows for an improved accuracy of 0.008 %. It will permit calibration in any of 12 different pressure units, using the existing weight set.

What's in the Box

P3116-KGCM2 Deadweight Tester

Series 3 nonmagnetic austenitic stainless steel masses

Accredited calibration report

Detachable lid

Adaptors

Operating fluid

Spare seals