- Description

- Specifications

- Documents

Features and Specifications

For professionals working in clean process industries, including facilities managers, production engineers and calibration technicians

Calibrate up to four tri-clamp sanitary sensors at the same time

Wide temperature range: 35 to 250 Celsius

Typical Heating Time: 35 to 100 C (25 min), 100 to 250 C (45 min)

Typical Cooling Time: 250 to 100 C (35 min), 100 to 35 C (55 min)

(-P) Process Input Module that measures various types of temperature sensors

Recommended fluid: Fluke 5014 Silicone, 50 centistoke

Excellent display accuracy of +/- 0.1 C provides 4:1 test uncertainty ratio (TUR) for critical applications

Easy to transport up stairs and across catwalks

Stainless steel casing withstands harsh sterilizing chemicals and is rust proof

Large color display indicates bath fluid temperature, setpoint temperature

Control indicator shows when the fluid is at setpoint and heating status

Easy to use and maintain

Global Fluke support and service

Optional overflow container

6109A-P-156 - Designed for Clean Process Applications

The 6109A bath is designed to calibrate a wide range of temperature sensors utilized in clean process manufacturing. This includes sensors used in pharmaceutical bioreactors (-10 to 100 Celsius), chemical reactors (200 Celsius), steam-in-place processes (122 to 140 Celsius), autoclave sterilization (120 to 135 Celsius), food storage freezers (-25 Celsius), and food processing (0 C to 220 Celsius).

These baths feature a large tank (106 mm in diameter and 154 mm deep) that can accommodate up to four sanitary sensors simultaneously. This allows for the calibration of a variety of sensors, regardless of their shape, length, or diameter, with additional space for a reference thermometer. The baths’ quick heating and cooling capabilities enable efficient calibration, reducing the time spent waiting for the bath to reach and stabilize at the desired temperature. This leads to an increase in calibration throughput and a reduction in costly production downtime.

The system also boasts an impressive display accuracy of +/- 0.1 Celsius, accounting for all potential sources of error, including calibration uncertainty, stability, uniformity, and repeatability. The 6109A bath comes standard with NVLAP accredited calibration.

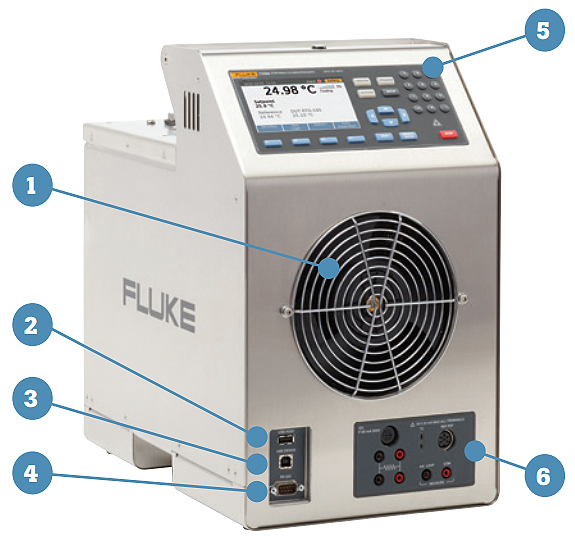

Front Panel Features

Fan: Cools the tank and heating devices

USB hostport: Used to record temperature data to a memory device.

USB device port: Used to control the bath remotely.

RS-232 port: Used to control the bath remotely.

Control panel (see control panel detail).

Process input module: The optional module includes a Reference PRT Connection and inputs to measure electrical temperature sensors for calibration.

Process Input Module Panel Features

Current fuse: Protects the Process Input Module and connected devices from accidental short circuit.

RTD terminals: A test RTD connects to these terminals. The graphic on the panel shows the circuit diagram for a four-wire RTD.

Reference PRT connector: A reference probe plugs into this socket. Recommended Fluke Reference PRTs are models 5615-9-A and 5626-12-A. Other Fluke Reference PRTs with Type A INFO-CON termination are also compatible.

Thermocouple input: A connector for a miniature thermocouple.

Transmitter terminals: A 4-20 mA transmitter connects to the two transmitter terminals labelled mA LOOP and COM.

Display Panel Features

Display: Shows information such as the fluid temperature and setpoint.

Softkeys: These keys correspond to the display icons directly above each key and perform a variety of useful functions. The functions change with the status of the display.

Mode keys: The monitor, setpoint, program, and the setup keys access different groups of settings. Some mode keys light up when the mode is active

Other keys: The number keys, cursor keys, and a SELECT/ENTER key enable you to make menu choices quickly and easily. Number keys let you enter decimal numbers.

Hot warning indicator: This indicator lights up if the fluid temperature is greater than or equal to 60 Celsius. This warns that the bath fluid, tank cover, and area around the tank are hot and should not be touched. If the bath is switched off, the indicator stays on until the bath reaches a safe temperature.

STOP button: Immediately disables heating and cooling and switches off the stir motor.

Take These Portable Baths Almost Anywhere, Including the Clean Room

The 6109A, weighing 16 kilograms (35 pounds), is designed with a stationary bail handle that allows most individuals to transport a bath single-handedly. This feature proves beneficial when the task involves navigating stairs, catwalks, and other challenging locations. The bath also has two indented handles at the bottom, facilitating its transfer from a shelf to a cart or workbench. A sealed cover safeguards against liquid leaks during transit.

The bath’s stainless steel exterior can withstand the potent chemicals used for sterilization in clean rooms. The decals, keypads, and feet, made from synthetic materials, are resistant to bacterial growth. The keypad is sealed to prevent moisture penetration, thereby protecting it from damage during cleaning or use in uncontrolled environments.

What's in the Box

6109A-P-156 Calibration Bath w/ Process electronics

Mains power cord

USB cable

Probe access cover

Transport tank cover

Printed safety information

Product CD

Report of calibration with label

Clamp-on ferrite (-P models)

Din connector (-P models)

Test lead kit (-P models)